THE AMERICAN HARDWOOD EXPORT COUNCIL (AHEC) PRESENTS ‘THE SMILE,’ A COLLABORATION BETWEEN ARCHITECT ALISON BROOKS AND ARUP AT THE LONDON DESIGN FESTIVAL.

The American Hardwood Export Council (AHEC) in collaboration with Alison Brooks Architects and Arup has brought a new landmark project to the London Design Festival that not only pioneers new applications of hardwood, but also brings the performance potential of such sustainable materials to one’s attention through the installation of a fun and memorable form that viewers can interact and engage with at the Chelsea College of Art Rootstein Hopkins Parade Grounds from 17 September until 12 October, 2016.

The Smile viewed from above in the Roostein Hopkins Parade Grounds. Image © AHEC, Photographers Dav Stewart and Jon Cardwell

‘The Smile,’ a curved and tubular structure, can be explored and inhabited by the public as one is invited to step inside its beamed shape measuring some 34 meters in length and 3.5 meters in height, a spectacular achievement when it comes to the marriage between material, shape and form that realizes the first ever ‘mega-tube’ made entirely from panels of hardwood cross-laminated timber.

Alison Brooks discusses the renders of The Smile in her studio. Image © AHEC, Photographer Jon Cardwell

“The Smile’s form implies that it will rock,” describes Alison Brooks, “so the form itself is an invitation to test whether the pavilion moves, and how it feels to walk in on a curved floor. A single door and ramp from the square invites visitors to enter – something like our archetypal image of Noah’s Ark. Inside the door light spilling from the ends of the arc will invite you to walk up the slope of the curve to balconies at either end, rather like looking out from the rail of a ship.”

Cleaning dust from the perforations in the American tulipwood CLT panels. Image © AHEC, Photographer Jon Cardwell

A ship-like sanctuary of a structure that, in terms of the research and advancements in material application that went into its creation, has been in the works for some time coming. “The Smile is not an installation at all, but something far more important,” furthered David Venables of AHEC. “It’s effectively the latest stage in a 10-year project that challenges the way hardwood can be used structurally. Rather than doing our experimentation in a laboratory, we do it in public.”

Props inside The Smile support the walls while the screwing takes place. Image © AHEC, Photographer Jon Cardwell

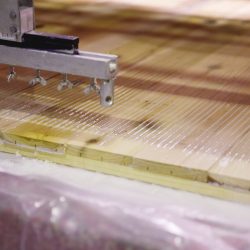

The material, cross-laminated timber (CLT), is an engineered timber that can be used to make the walls and floors of entire buildings. It’s construction is layered, with the wood fibers being turned at right angles in each successive layer, the results of which are a panel bearing equal strength in both directions, similar to plywood. Weight for weight, however, CLT is actually stronger than concrete and can be “machined to incredibly high tolerances,” making it an ideal choice for both prefabrication and rapid assembly. Furthermore, while CLT is often made from softwoods such as the spruce (Christmas tree) we are all familiar with, the experimentation in developing CLT from tulipwood being investigated here by AHEC and Arup has shown even stronger results, that nonetheless also come with an increased aesthetic character.

Allison Brooks and ‘The Smile’ Image © AHEC, Photographer Guy Bell

“It’s a very interesting wood,” Alison Brooks affirmed. “ It has wonderful grain and color variation as well as a kind of sheen, so the grain is tight and smooth. Tulipwood can be selected to be clear and knot-free, offering a really clean-looking alternative to softwoods. I love the way the strips of wood in cross-laminated timber have a direction that expresses how the structure is working.”

The Smile illuminated at night , seen from the west side of the parade grounds. Image © AHEC, Photographer Dav Stewart

The Smile is the first project in the world to use large hardwood CLT panels, with the entire structure being made from just 12, each of which can measure up to 14 meters in length and 4.5 meters in width. The work falls fittingly in line with AHEC’s ever-growing list of creative projects (The Wish List and Endless Stair being predecessors) presented through the London Design Festival and, just as a smile shared has equal impact on both giver and receiver, these installations not only prove fulfilling for the intrigue of their design and forms, but also for the continuous development and demonstration of the performance potential of hardwoods they exhibit.

‘The Smile’ Image © AHEC, Photographer Guy Bell

www.thetulipwoodsmile.info

www.americanhardwood.org