CALMIX MORTAR IS A LIME-CEMENT MORTAR BRAND THAT OFFERS A WELL-VENTILATED, FLEXIBLE, AND ENVIRONMENTALLY FRIENDLY MATERIAL

TEXT: PICHAPOHN SINGNIMITTRAKUL

PHOTO COURTESY OF CALMIX

(For Thai, press here)

Lime, a natural material that has been associated with building construction for thousands of years in ancient sites around the world. Throughout the development of materials science in terms of properties, performance, and mission of development in the new era, there has been the creation of lime products that reduces greenhouse gas emissions. A construction material choice that loves the earth and loves consumers.

Calmix Mortar is a lime-cement mortar brand that offers a choice of mortar products for construction. With hydrated lime, a natural material with weather-friendly properties, especially in terms of ventilation, lime can therefore be used for both exterior and interior masonry and brick plastering work.

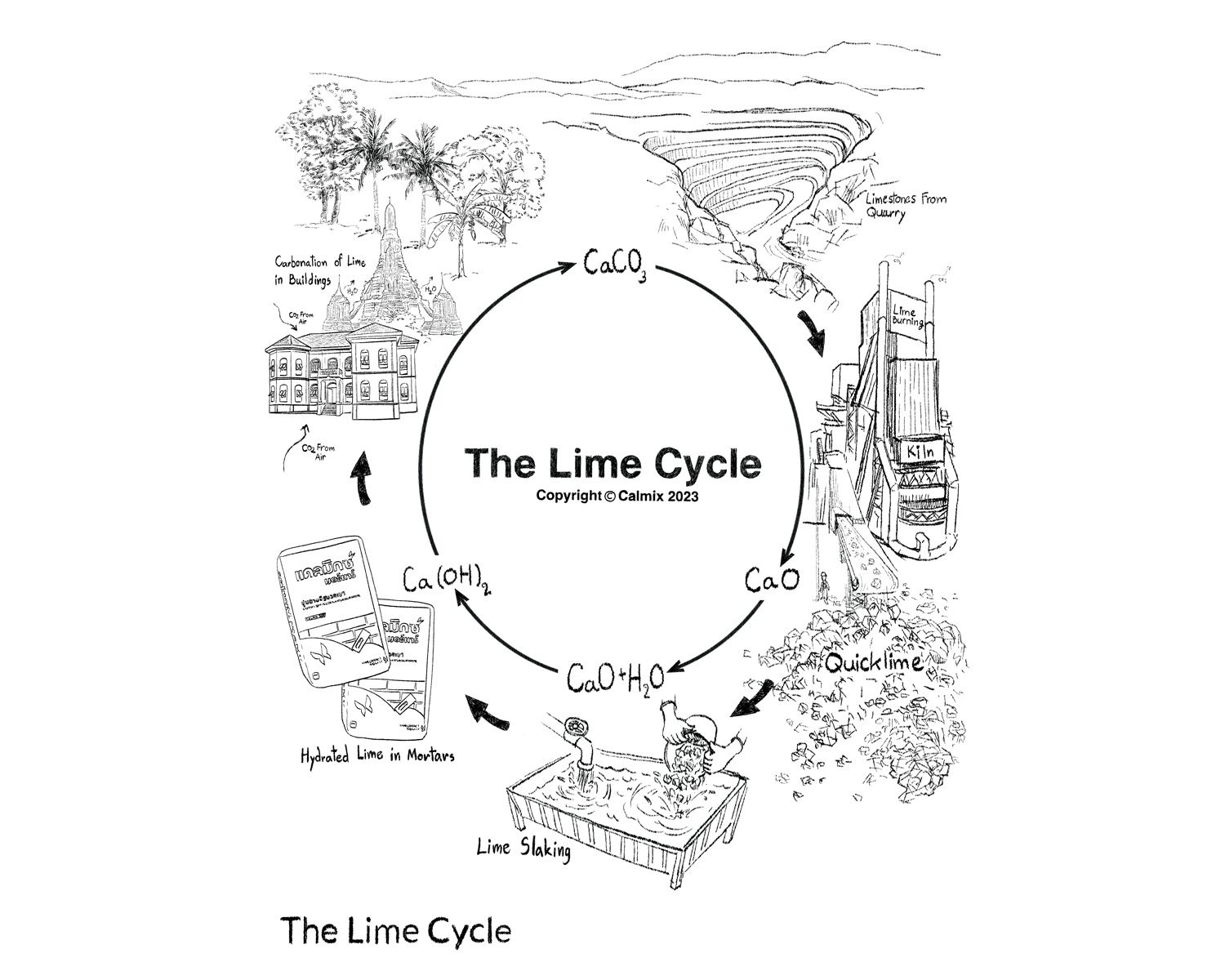

To illustrate the lime cycle and its environmental friendliness, we may start with natural limestone that has been calcined to produce quicklime before further processing into lime slaking and finally to lime-cement mortar products for construction. Throughout the process, the lime will absorb carbon dioxide in the atmosphere and transform into calcium carbonate, or limestone, that becomes part of the building.

The Lime Cycle

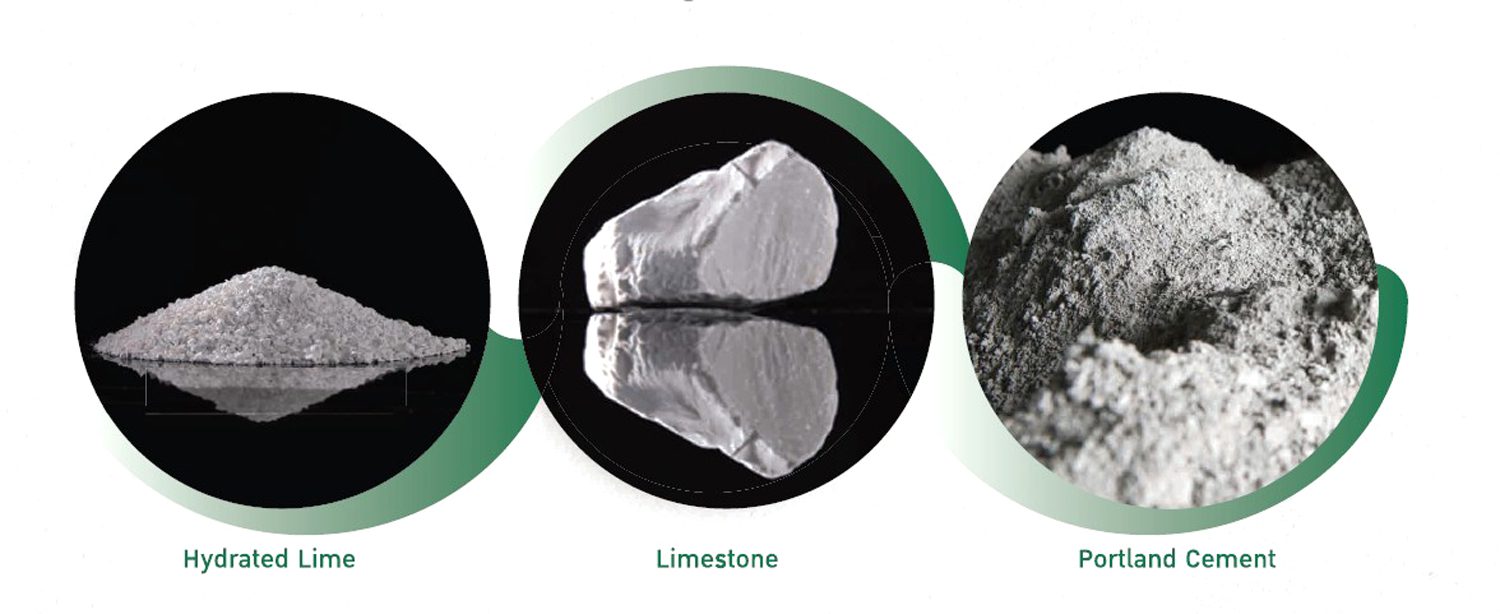

Hydrated Lime, Limestone, Portland Cement, Main ingredients of Lime-Cement Mortars

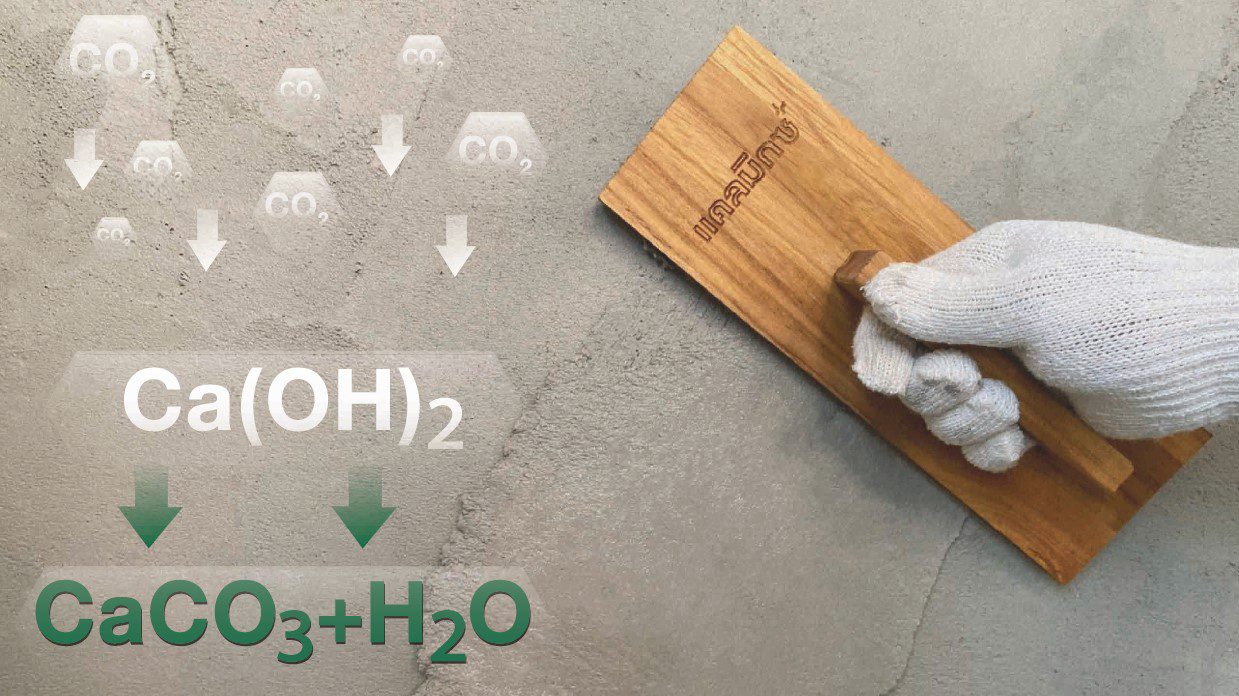

The lime mortar that turns itself into limestone on the building itself increases the strength of the surface. It also helps to seal small cracks. Also known as Self-Healing. When combined with the properties of lime-cement mortar that are well ventilated and flexible, it allows the thermal expansion of the brick to increase. This gives lime both material performance properties, as well as a role in reducing greenhouse gas emissions through construction work.

The outstanding feature of lime and its properties throughout the cycle inspired Calmix Mortar to develop lime as a mixture with cement and manufacture it as a ready-made lime-cement mortar. The main objective is to create a material that is environmentally friendly, considering the property that the lime cement can absorb carbon dioxide from the atmosphere to be stored on the surface of the building along with the creation of fresh air within the living space.

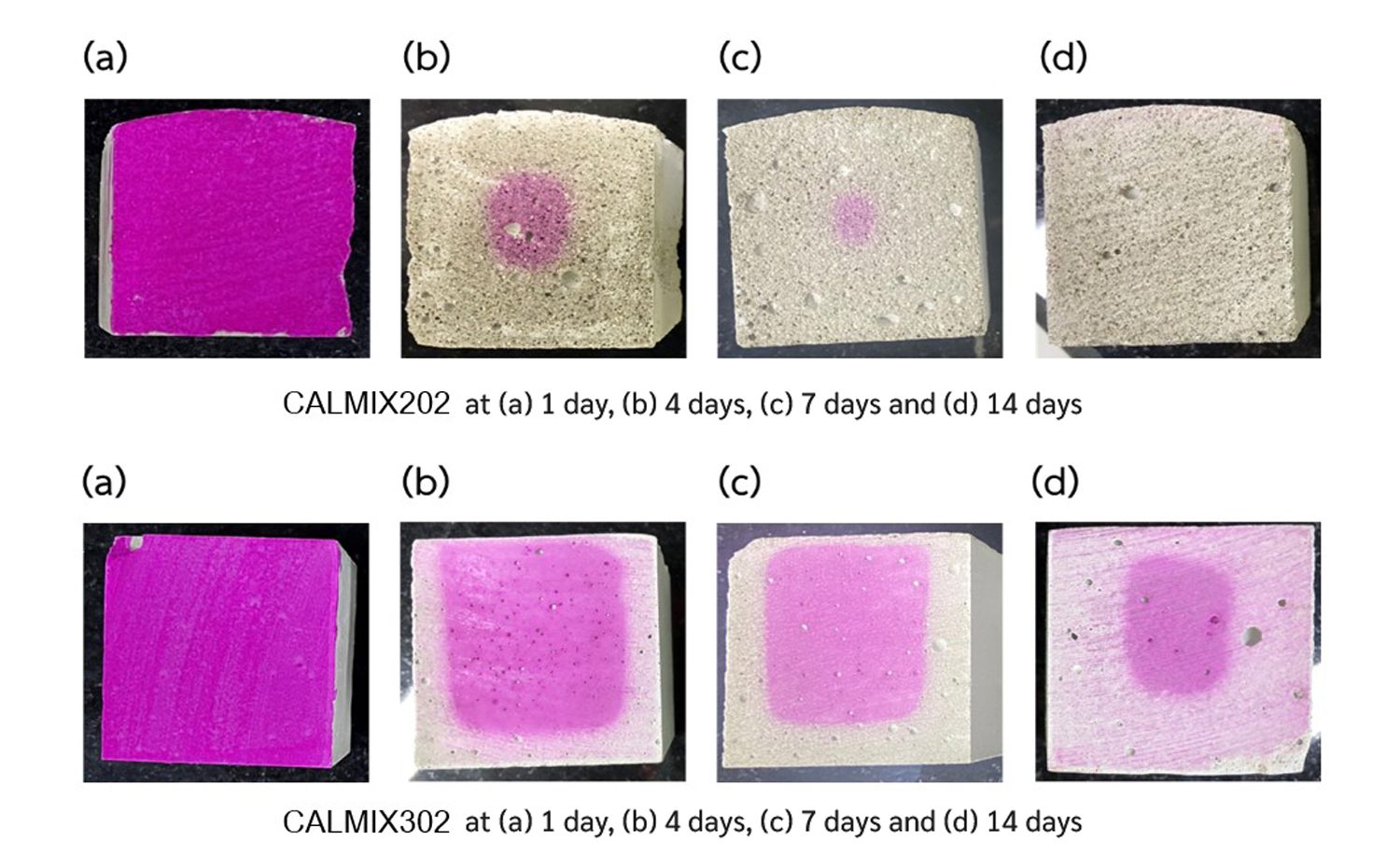

The proof of lime-cement mortar’s properties came through real tests in the laboratory with a scientific method to detect the process of limestone formation (carbonation) that absorbs carbon dioxide from the atmosphere. The results of Carbonation Depth experiment showed that the depth of the gas absorption from the outer surface expanded more broadly with the age of the lime cement. This test was performed on Calmix Mortars for the masonry and thin skin finishing.

Carbonation Depth experiment, demonstrated the depth of the gas absorption from the outer surface which expanded more broadly with the age of the lime cement.

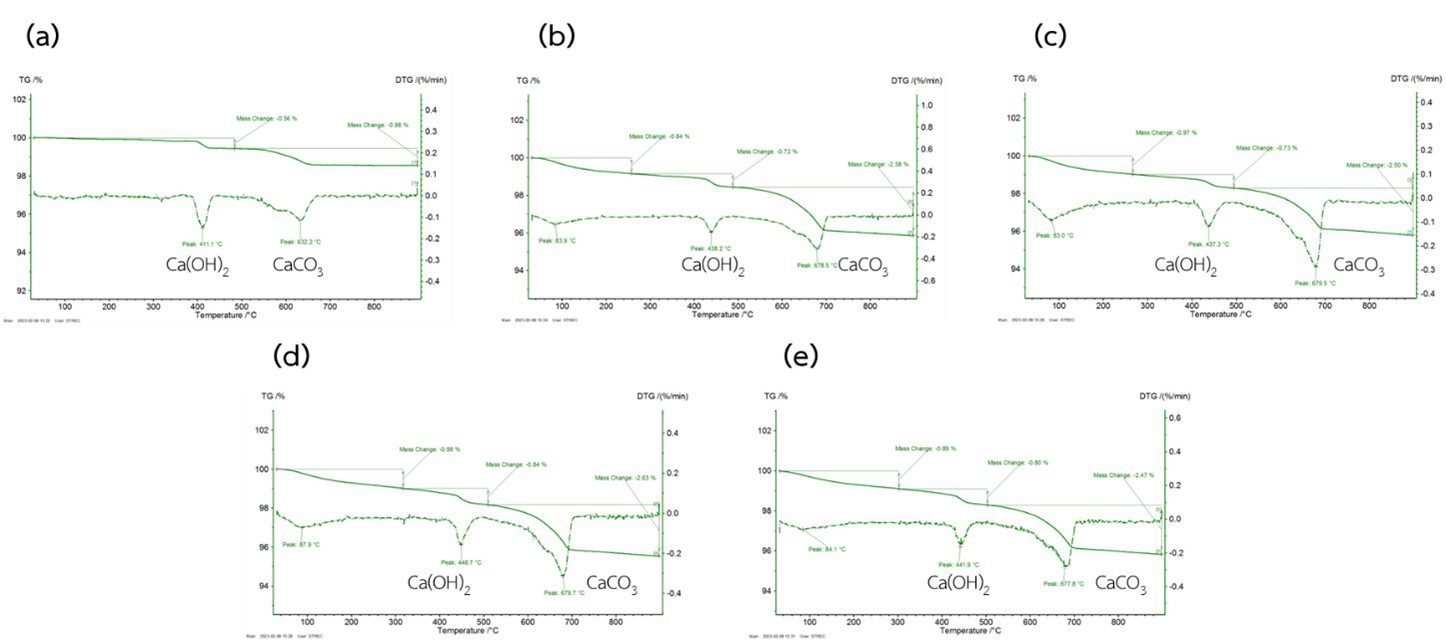

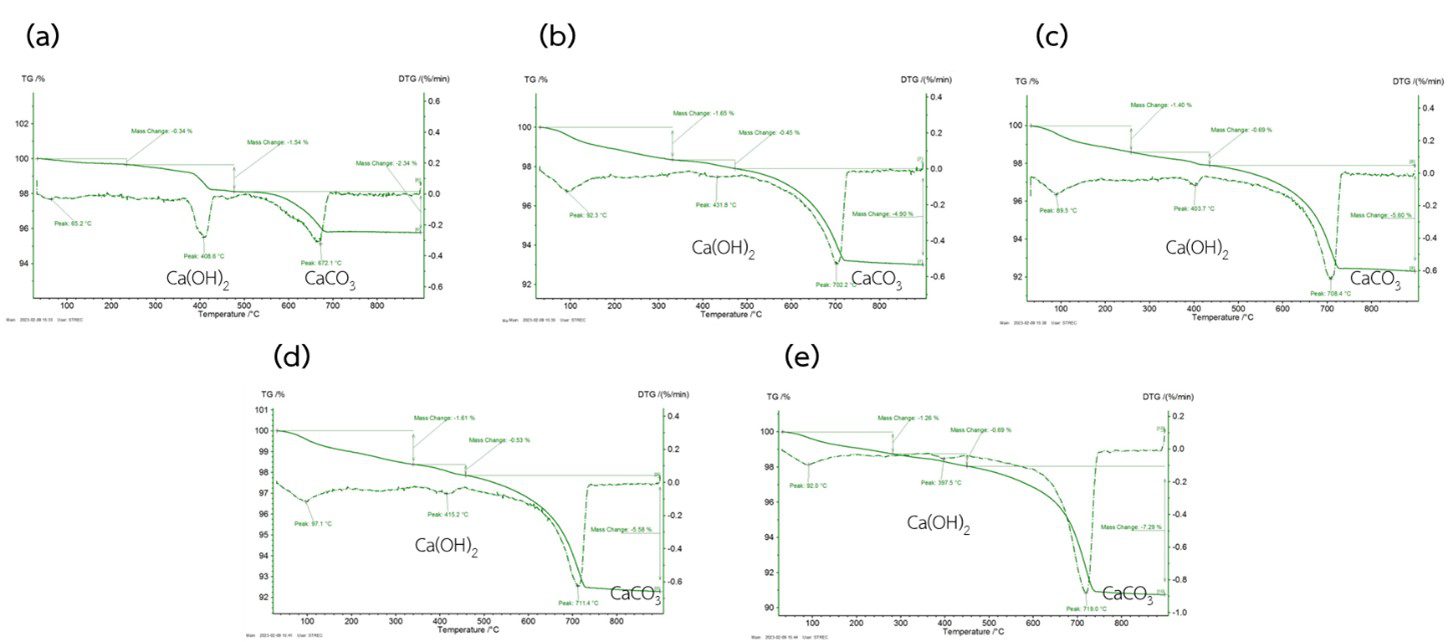

Another test is the Thermogravimetric Analysis (TGA), which analyzes the chemical weight changes in lime-cement mortars depending on the age of the cement. The results show that over time the weight of lime decreased while the weight of limestone increased, which is caused by the absorption of carbon dioxide in the atmosphere.

These two laboratory experiments revealed that lime-cement mortars had prominent properties to absorb carbon dioxide, and, therefore, the product is environmentally friendly. Along with the properties of cement that allow it to breathe well. It is porous to let air in and out, like a breathing wall. All in all, durability is important. therefore leading to sustainable construction use in architecture.

Graph depicted weight between Hydrated Lime (CaOH2) and Limestone (CaCO3) over the course of 1, 4, 7, 14 and 28 days on Calmix 202 Lightweight Block Masonry Mortar

Graph depicted weight between Hydrated Lime (CaOH2) and Limestone (CaCO3) over the course of 1, 4, 7, 14 and 28 days on Calmix 302 Grey Skim Coat

Calmix Mortars products cover all aspects of building construction, including general wall mortar, brick, concrete block work, and lightweight block masonry mortar that requires a high level of strength. While for plastering work, it can be applied for general plastering for plastering bricks and building blocks. Aerated concrete plaster focuses on heat protection that can be plastered both inside and outside before painting, and concrete block plaster can be plastered on the concrete surface or by laying materials over surfaces that are oily or non-absorbent.

For thin-surface plastering work or skim coating, it can be worked with white thin-surface plastering products and decorative plaster with a thin gray skin for surface preparation, painting, and wallpapering. Or use smooth plaster over another layer of plaster for smoothness. And lastly, the cement for leveling the floor, can be used as a foundation layer, to plaster over the floor surface, over the insulation embedded under the floor, or as a raised base for the interior area.

Calmix Mortar White and Grey Skim Coat

Calmix Mortar Floor Screed

As for the production process, lime-cement mortar is an innovation in the Thai construction industry; it promotes the quality of functional properties and participation in reducing global warming simultaneously in the product, starting from the selection of crushed limestone, lime, cement, and raw materials with machinery and production technology from Germany, one of the world’s leading producers of ready-made mortar.

When delivering the products to the users, Calmix Mortar also has a team of engineers and technicians to provide guidance and advice on product usage. Not only for customer satisfaction, but also for the most efficient use of this love-earth mortar in construction and architecture. This is considered the key to creating materials that solve the global warming crisis from greenhouse gas emissions in a complete cycle.

Because the construction business today needs more speed to work, product qresearch and development to meet the needs of users is an important mission of the product developer, along with a global commitment to the environment. This is one of the key topics of the BCG, a national agenda to drive the Thai economy towards the international level.

Calmix Mortar wants to be one of these key chains in pushing forward the Thai construction industry, through material innovation, product research and development, and the process of use, so that lime-cement mortars can be a part of promoting the policy of zero greenhouse gas emissions to be realized. This will benefit all sectors in the field of construction and the environment in the future.