THE PRECAST CONCRETE PLANTERS ARE MODIFIED TO SERVE AS THE BUILDING SURFACES OF COLLAGE DESIGN STUDIO’S OFFICE BUILDING, EXPOSING THE RAW BEAUTY OF CONCRETE AND BREATHING NEW LIFE INTO THE PLANTERS

TEXT & PHOTO: XAROJ PHRAWONG

(For Thai, press here)

Modifying or reimagining a material to serve a different purpose from its intended use can open up endless possibilities and alternatives, thereby imbuing it with more diverse meanings,. The design of Collage Design Studio’s new office building embodies this ethos. Situated in the densely populated residential area of Ratchadaphisek 32 in Bangkok, the structure reflects the studio’s desire to have its own space, departing from its previously rented premises, in order to cater to its specific needs and activities.

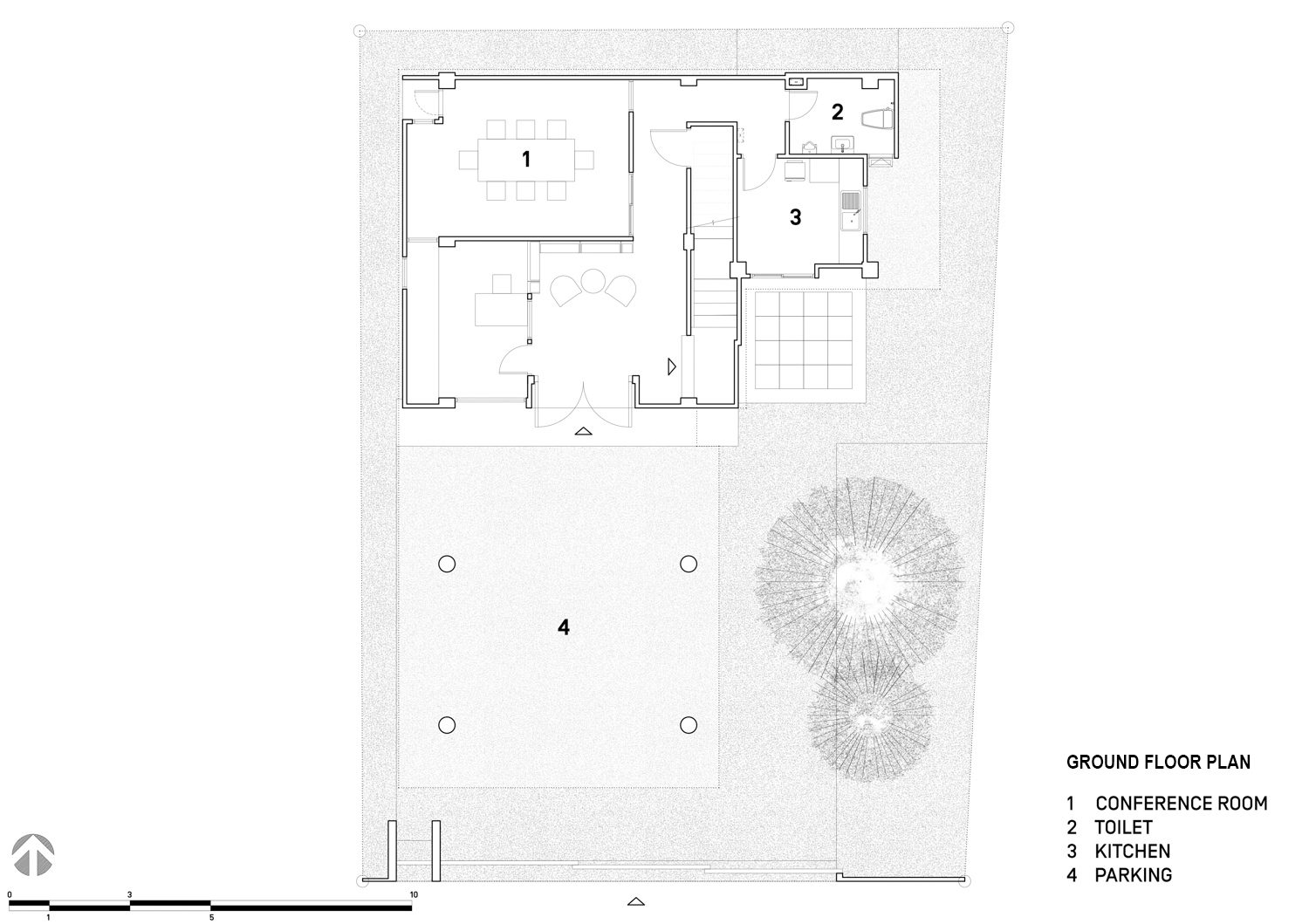

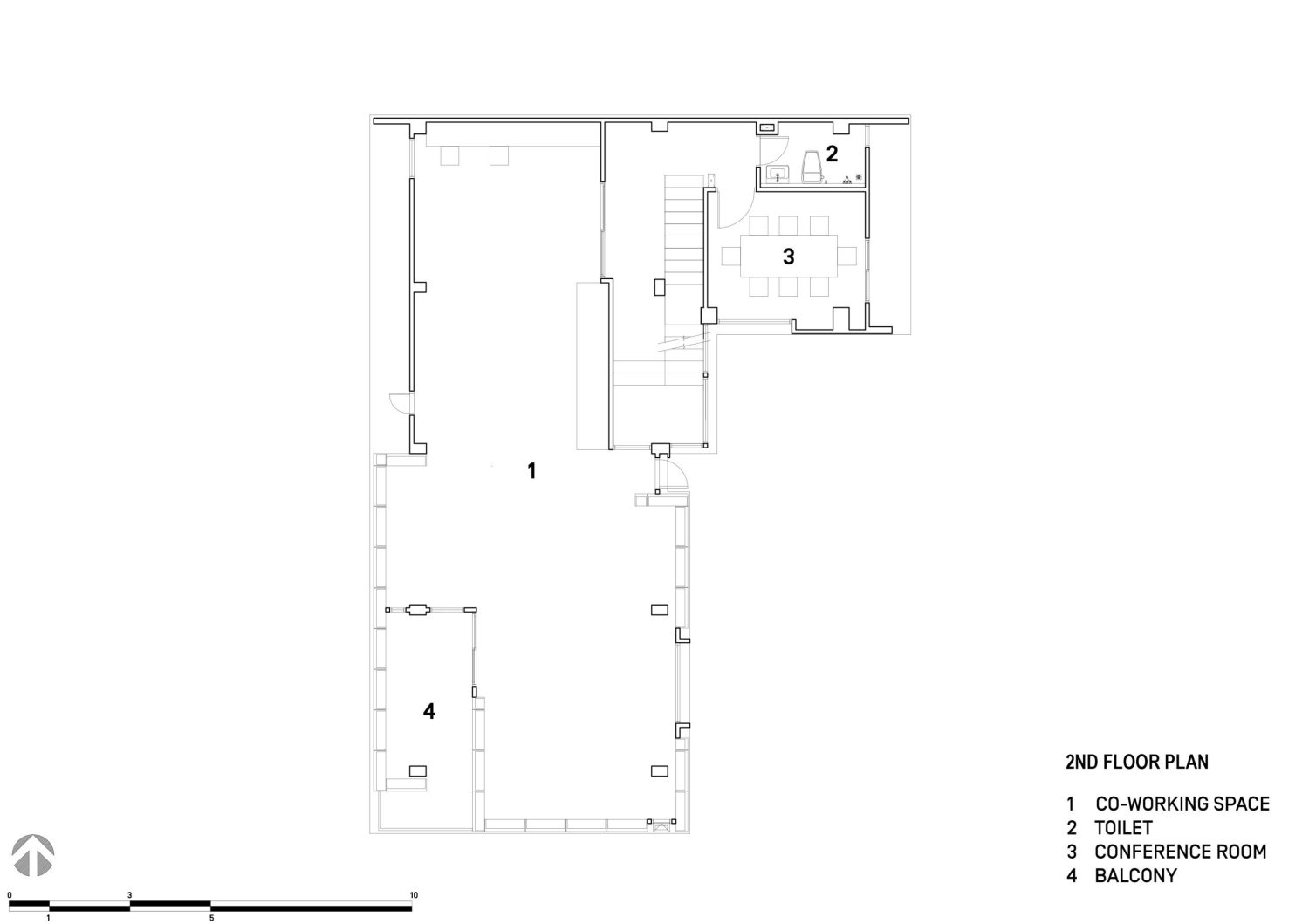

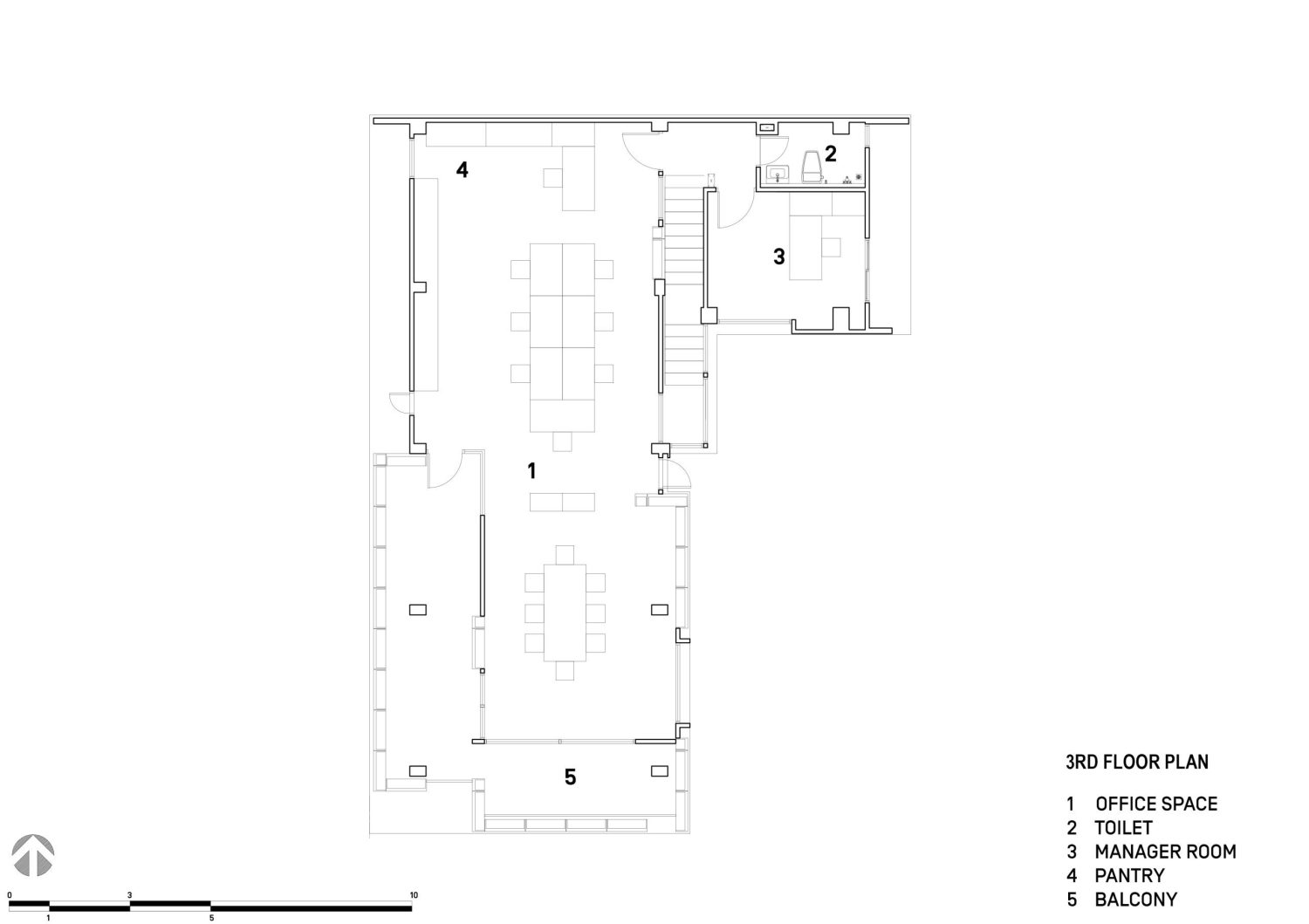

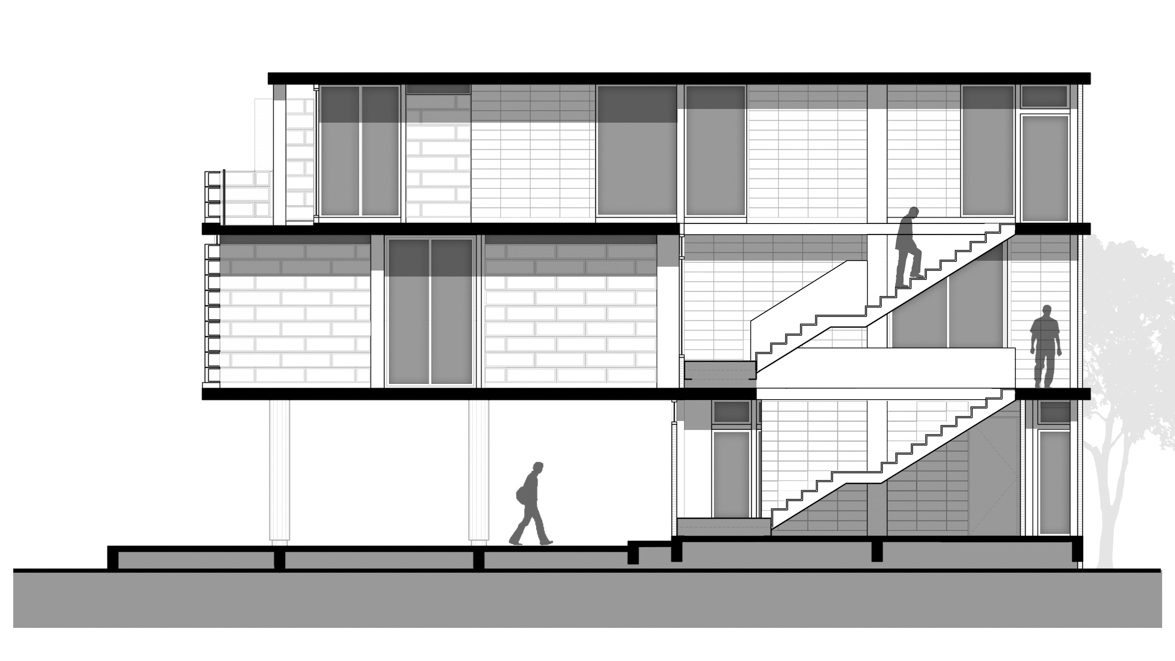

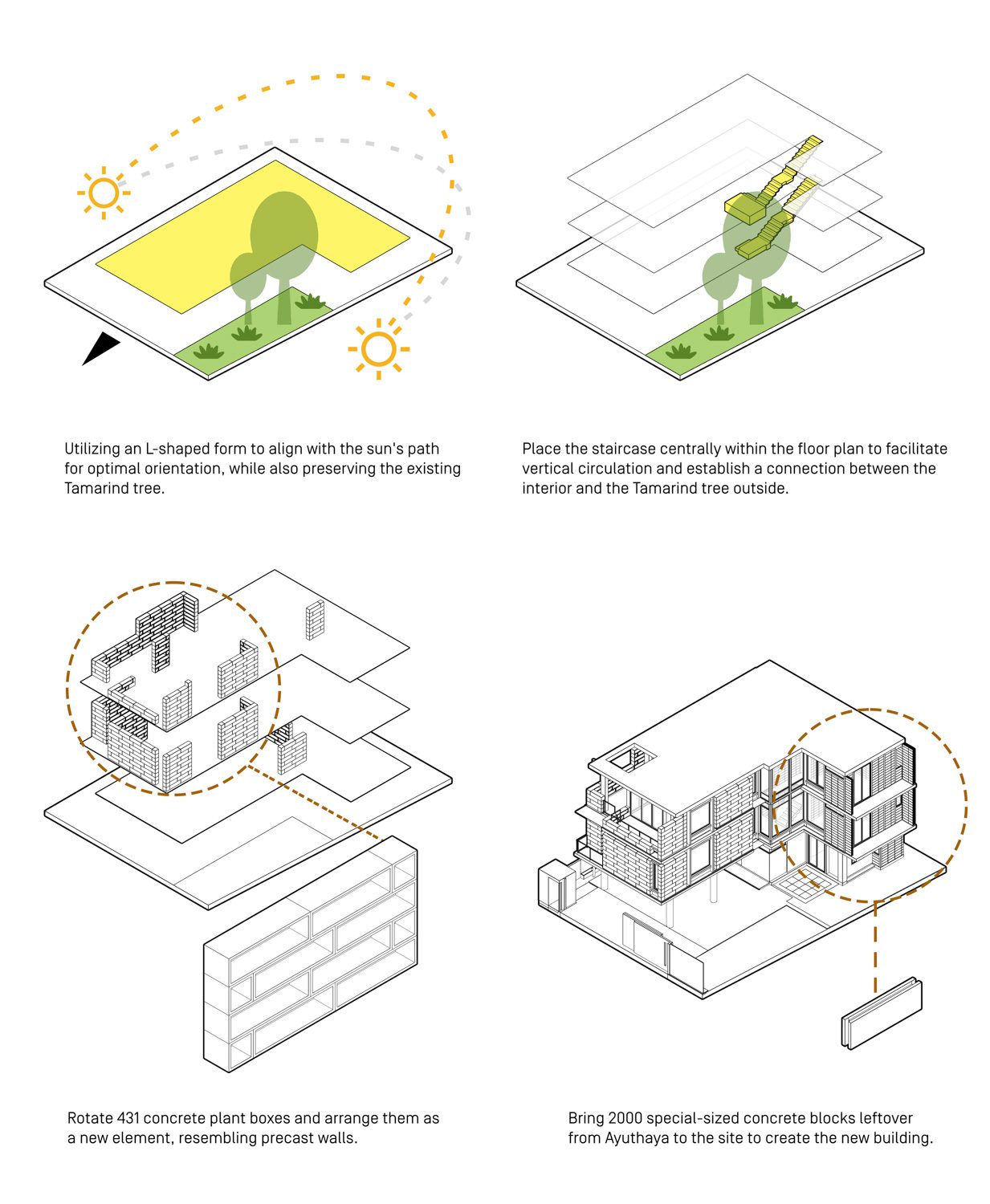

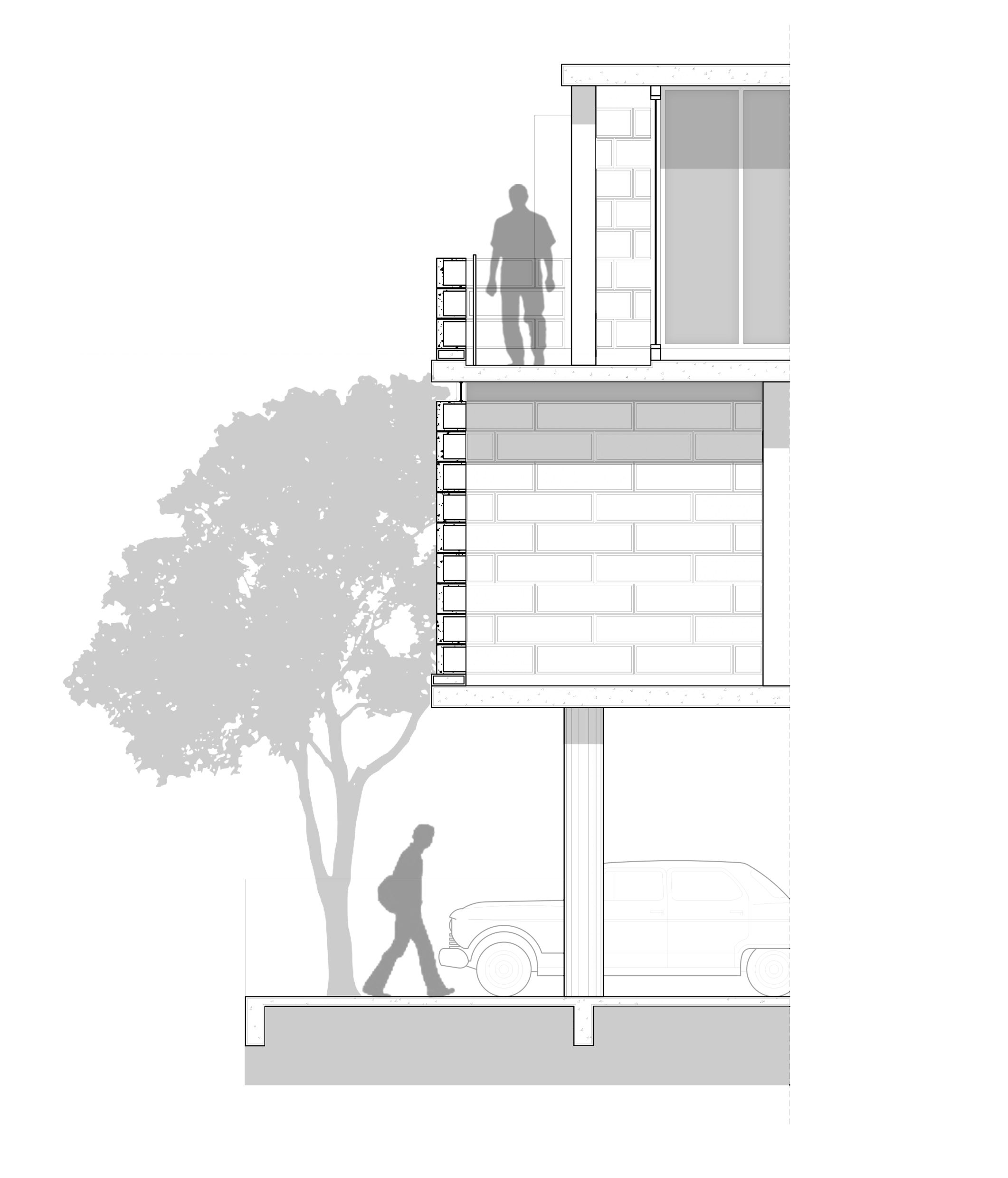

The exposed-concrete edifice serves a multitude of functions. The design divides the usable spaces into three levels, all fitting into the L-shaped layout, with its longer side oriented in a north-south direction. Divided into three levels, the design seamlessly integrates into the L-shaped layout, with its elongated axis aligned north-south. At the shorter end of this configuration, essential service areas such as restrooms, a kitchen, and a stairway fulfill their functional roles while also acting as a buffer against the sun’s rays for the main building’s mass. Beyond its primary function as an architectural office, the building ingeniously incorporated supplementary spaces to enrich its utility and appeal, with each level meticulously allocated to accommodate diverse activities.

On the first floor, a semi-outdoor expanse caters to both leisure and collaborative endeavors, while a commercial area hints at its potential transformation into a future café. Ascending to the second floor reveals a dynamic environment primed for communal gatherings, complete with meeting rooms and a flexible co-working space. The third floor stands as the heart of the building’s program, housing the studio’s main office space. Service areas are discreetly positioned along the western wing. Within the studio’s main workspace, an elongated rectangular layout follows the north-south orientation, fostering an expansive and interconnected open-plan environment. Despite the solidity of the walls, the interior ambiance is characterized by subdued illumination, punctuated by openings towards the north and west. The raw beauty of exposed concrete permeates the space, celebrating its intrinsic qualities without the need for embellishment. The architects designed the northern terrace as a recreational space for the staff members, providing unobstructed views of the city’s skyline from the third floor thanks to a high vantage point above the surrounding two-story residential buildings.

The project’s most intriguing aspect is the architectural choice that addresses budgetary constraints by factoring in both material and labor costs. Namely the innovative idea of employing precast concrete planters, readily available on the market, as the primary façade material for the building by ingeniously rotating them at a 90-degree angle. This strategy aimed not only to streamline construction time but also to mitigate any surface imperfections inherent in precast concrete, known for its factory-made consistency. Moreover, it offered the dual benefit of minimizing interior finishing expenses, as the planters seamlessly doubled as internal shelving units. At the outset, the architects scoured the market for concrete planters but encountered a stumbling block with production standards. Most were handcrafted using wooden molds, which were cheaper but yielded irregular surfaces unsuitable for interior adaptation.

Undeterred, they embarked on a quest, casting a wide net across various sources until uncovering a specialized facility in Lopburi province, adept at crafting steel-cast concrete planters. These units boasted smooth surfaces straight from the mold, without the need for additional finishing touches and ensuring a flawless façade finish. The genesis of this inventive solution stemmed from a problem, ultimately resulting in a bespoke building envelope fashioned from precast concrete planters, each measuring 30x30x100 centimeters. The design ended up arranging the planters in a stretcher bond pattern along the main wall, adorning the edges with 30x30x30 centimeter units as end caps.

Not long after construction began, an issue arose that threatened to delay the project significantly. The production of concrete planters took longer than anticipated, creating a delay in the building process as these planters were crucial for cladding the entire structure. To tackle this setback, a reassessment of materials to fortify the building envelope became imperative. Considering the project’s limited budget, the architecture team decided to utilize concrete blocks as a solution. They found an opportunity at a factory in Ayutthaya province, where surplus stock of several thousand blocks was available for purchase at a price even lower than the market rate. These blocks, measuring 19x59x7 centimeters, were then employed to reinforce the southern and eastern walls. Born out of necessity, the inventive approach gave rise to the cleverly improvised building shell.