CLOUD HOUSE, A HOUSE WRAPPED IN A CYLINDRICAL PRECAST CONCRETE FAÇADE THAT WAS DESIGNED BY BACKYARD ARCHITECT

TEXT: KARN PONKIRD

PHOTO: THANES PIAMNAMAI

(For Thai, press here)

The client’s brief called for a residence in Nakhon Pathom, one that would accommodate a three-generation family, with ample space for children to play and for the grandparents’ visits. Equally important was the ability for the home to function as a seamless home office, should the need arise for remote work. The result is ‘Cloud House,’ a 1,200-square-meter dwelling that responds to these needs with thoughtful design and innovation. Both architect and client were united in their desire to experiment with architectural materials, which became a defining aspect of the project.

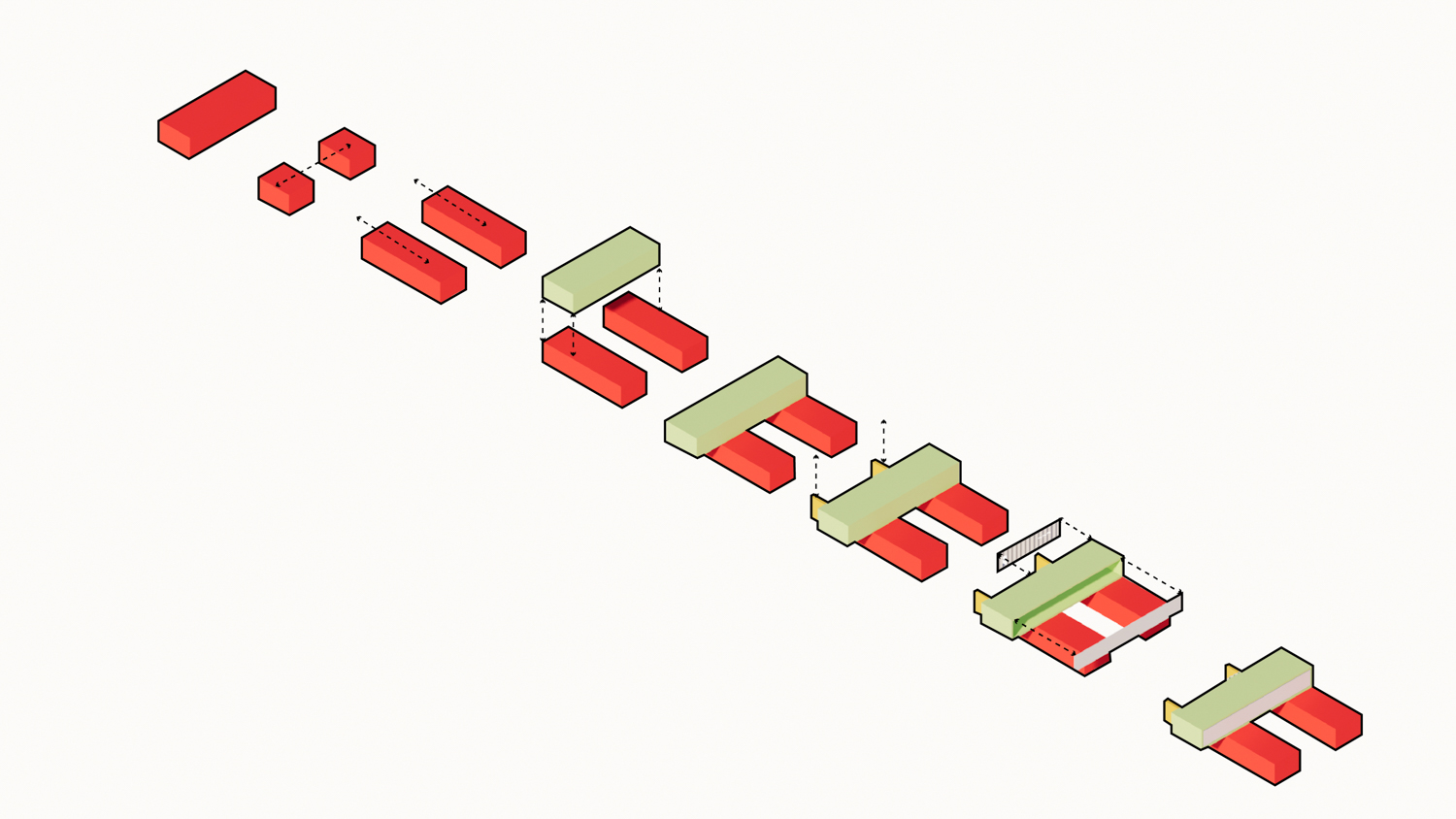

Meechai Jaroenphon, an architect at Backyard Architect, shared that the design process began with the client’s preference for a U-shaped home, which was then integrated with a well-considered zoning of activities. From there, the design focused on delineating the privacy of each space, with the second floor reserved exclusively for the family’s private areas. This level would be where the core activities of daily life and relaxation takes place. The challenge was to create a space that felt both secure and light, without the oppressive weight of a conventional, enclosed home. The careful use of openings to invite natural light was integral to achieving this balance. As these concepts took shape, the overall massing of the house gradually emerged. To further clarify the vision, the architect used a straightforward Lego block model to communicate the idea to the client. The design was immediately well-received, and with this understanding, the concept was further refined. The client, eager to elevate the design, expressed a desire for the house’s architecture to be more ‘special’ than an ordinary box-like form.

Meechai further explains that the culture at Backyard Architect, in every project, goes beyond simply meeting the client’s requirements and ensuring the architecture adheres to professional standards. The team believes in the importance of what they ‘take away’ from each project as well. This involves the gradual accumulation of knowledge, a deepening understanding of materials, and the invaluable insights gleaned from experimentation—an ongoing process of learning that simultaneously nurtures the growth and development of the team.

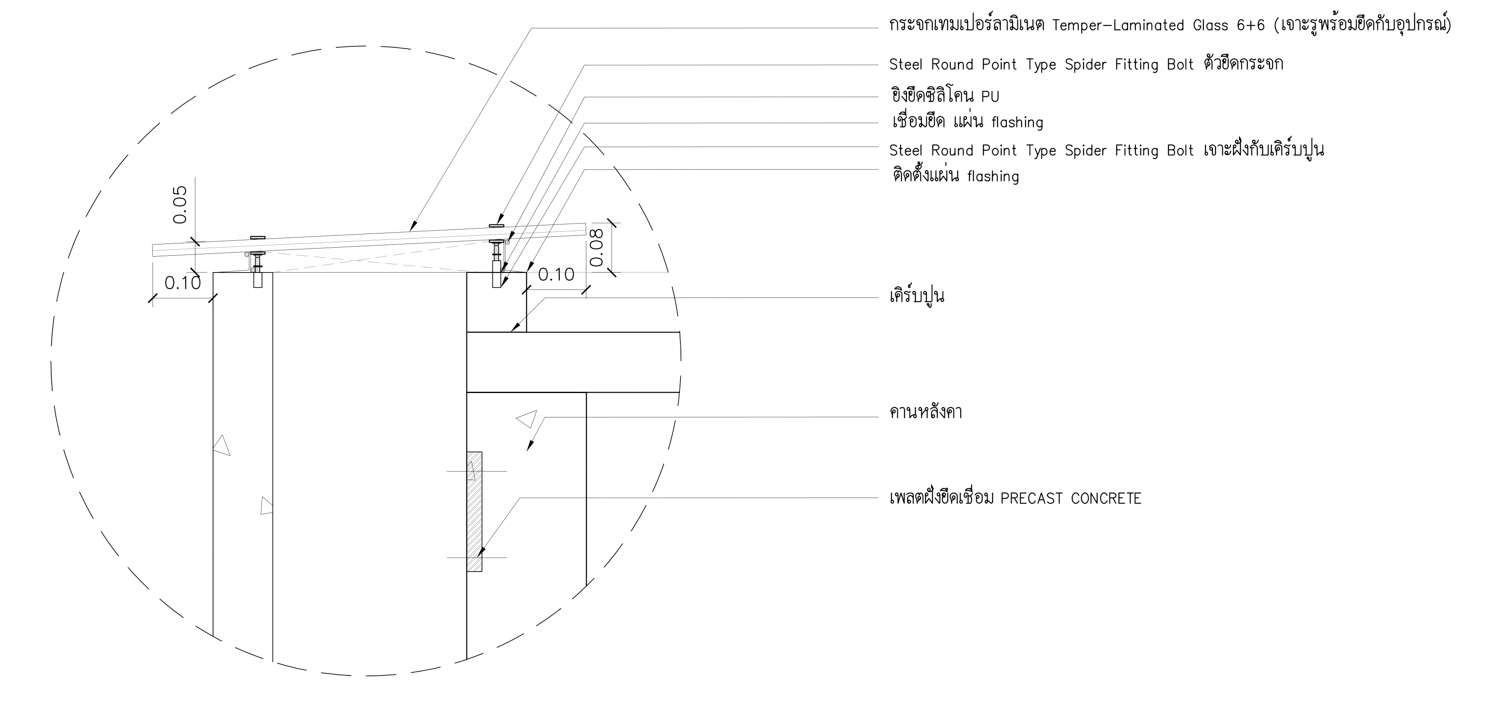

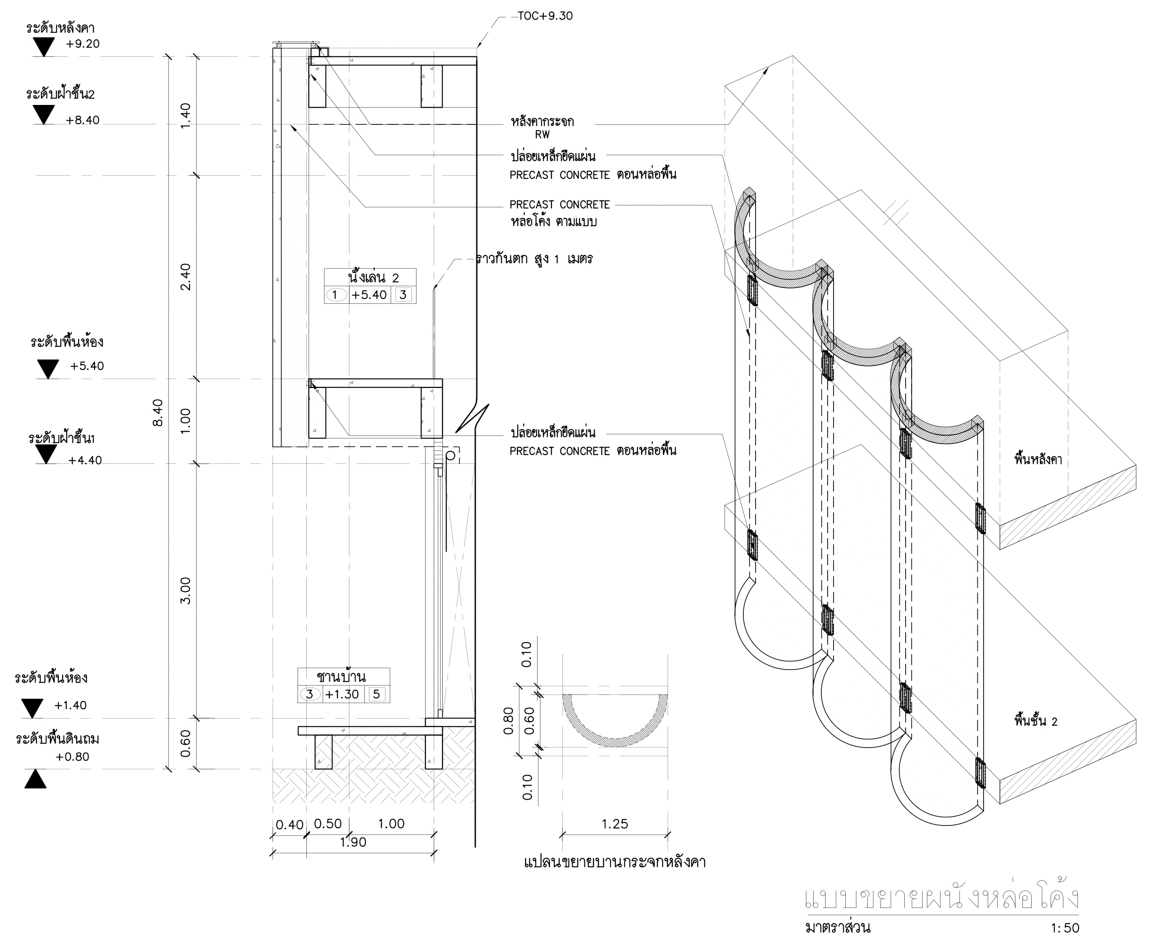

Meechai’s passion for concrete architecture, inspired by the works of distinguished architects such as Amorn Sriwong and Rangsan Torsuwan, played a crucial role in the design of the façade enveloping Cloud House. The façade became a platform for challenging the potential and limitations of concrete in contemporary construction. The goal was to take the façade beyond the conventional box-shaped home while still maintaining the essential qualities of security and heat protection. This was achieved through a carefully calibrated manipulation of light, selecting precise moments for sunlight to interact with the material in a way that would create the desired effect. Given the client’s desire to avoid high interior temperatures and excessive sun exposure, the design team turned their attention to the path of the sun, studying the times when sunlight would fall on the building. To ensure the sunlight would only be present for brief intervals, the architect focused on the period between 11:00 and 12:00, directing light from above. Curved openings were strategically placed to allow sunlight to filter through during this specific time frame. The dimensions and orientation of these openings were tested using simulation software, ensuring the light would enter in the desired form and at the ideal moment. This process culminated in the selection of cylindrical forms to encase the family’s living space.

Drawing from years of experience working with cast-in-situ concrete, ranging from small-scale applications to the casting of large walls, the architect was well aware of the challenges involved in achieving the desired quality when forming curved concrete shapes on-site. Variables such as labor skill, weather conditions, and engineering constraints all contributed to the difficulty of controlling the quality of the work. Moreover, the client would bear the risk of having to demolish and recast the wall if the form and quality of the finished piece did not meet expectations, resulting in unnecessary cost overruns. The architect thus saw this as an ideal opportunity to experiment with precast concrete, which would address many of the on-site quality control challenges. Precast allowed for a more reliable and consistent outcome while also providing the team with a chance to develop new skills in working with a familiar material (concrete) in an unfamiliar process (precast).

The architect explained that, traditionally, precast walls have been associated with high-rise buildings and large-scale developments that require mass production. However, the decision to use precast in this project provided an opportunity to learn that, with meticulous design and careful planning, precast concrete can also deliver significant time and cost savings in low-rise residential projects. By thoughtfully designing the shape and method of attaching the precast panels to the structure, the architect was able to collaborate with the precast factory to refine the details. This collaboration included site visits by the precast team to ensure precise measurements, preventing any potential issues when the panels were lifted into place. Despite the careful planning, some unforeseen challenges arose. One key issue occurred when the length of the precast panels fell short of covering the entire height of the second floor, which measured 5 meters. This limitation surfaced after the client requested a higher ceiling for the second floor, while the mold for the precast panels could only accommodate a maximum length of 4.8 meters. Extending the mold to meet the client’s request would have doubled production costs due to the relatively small volume of the project. As a result, when the precast panels were installed, a gap emerged between the joint of the first and second floor masses. This created an unexpected but visually striking effect, where the second-floor mass appeared to ‘float’ above the lower level, giving the design a lightness and ethereal quality that added an unexpected, yet captivating, dimension to the overall composition.

The challenges encountered throughout the construction process became invaluable opportunities for daily learning and growth. With each obstacle, the team gained deeper insight and experience. The inherent imperfections of the materials, such as the natural variations in concrete, including unexpected marks or surface textures, became defining features of the design. These unpredictable details, far from detracting from the project, added depth and character to the architecture, grounding it in its specific context. Ultimately, when these elements coalesced into a home that fulfilled the residents’ needs and desires, it was these very imperfections that infused the building with life, Meechai concluded.